Timber LVL formwork is an essential component in construction projects, particularly in the concrete industry. It provides temporary support and mold for concrete structures, ensuring their stability and form during the pouring and curing processes. However, before engaging in any construction project involving timber LVL formwork, it is important to have a clear understanding of the pricing aspects associated with it. This article aims to provide you with insights into timber LVL formwork prices, helping you navigate this crucial aspect of your construction project effectively.

Defining Timber LVL Formwork

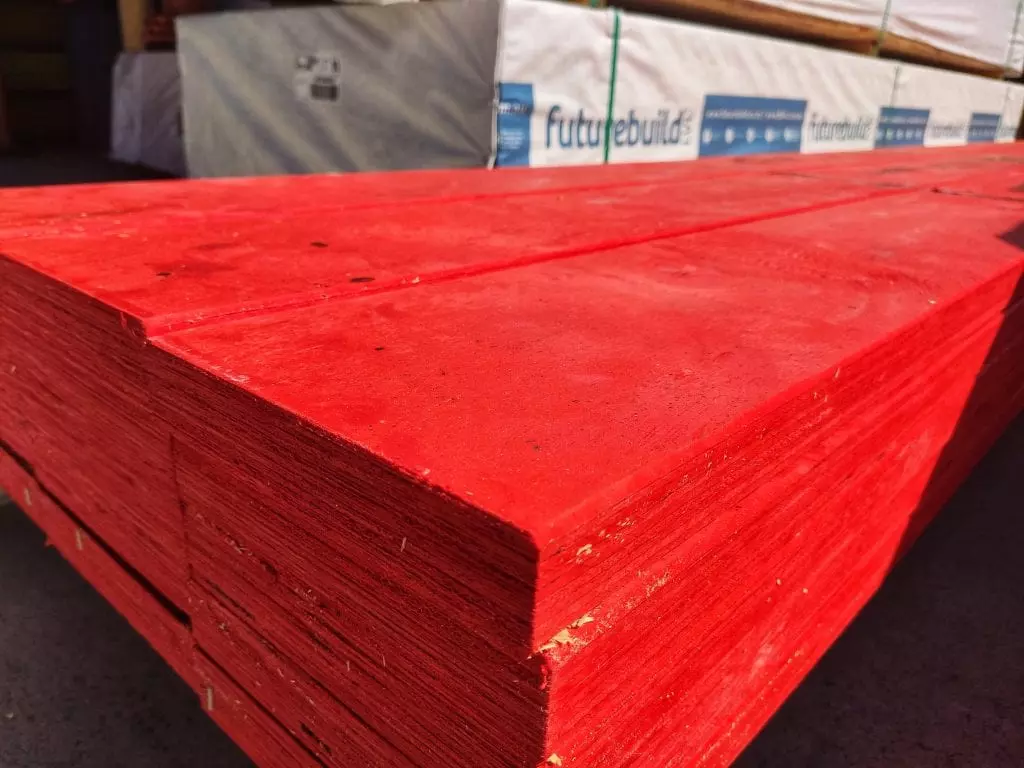

Before diving into the pricing intricacies, let’s start by defining timber LVL formwork. LVL, or laminated veneer lumber, is a strong and durable engineered wood product made by layering thin wood veneers together with adhesives. It is commonly used in construction due to its high strength-to-weight ratio and dimensional stability.

Furthermore, timber LVL formwork is known for its ease of assembly and disassembly, saving valuable time on construction sites. The lightweight nature of LVL also makes it easier to handle and transport, reducing labor costs and improving efficiency. Overall, timber lvl formwork prices offers a reliable and cost-effective solution for concrete construction projects of all sizes.

Timber LVL formwork serves as a temporary structure that supports the weight of wet concrete during the pouring and hardening processes. It consists of panels and beams that are interconnected to create a framework, which not only holds the concrete in place but also provides support and stability. The formwork is typically removed once the concrete has cured, leaving behind a solid and finished structure.

One of the key advantages of using timber LVL formwork is its versatility. It can be easily customized to fit various shapes and sizes, making it ideal for complex architectural designs. Additionally, timber LVL formwork is eco-friendly as it is made from sustainable wood sources and can be reused multiple times, reducing waste on construction sites.

The Basics of Timber LVL Formwork

Timber LVL formwork serves as a temporary structure that supports the weight of wet concrete during the pouring and hardening processes. It consists of panels and beams that are interconnected to create a framework, which not only holds the concrete in place but also provides support and stability. The formwork is typically removed once the concrete has cured, leaving behind a solid and finished structure.

When it comes to construction projects, the quality of the formwork is crucial for the overall success of the build. Timber LVL formwork offers excellent dimensional stability, ensuring that the concrete retains its desired shape and strength as it cures. This precision and reliability make timber LVL formwork a preferred choice for contractors and builders looking to achieve high-quality results.

Key Components of Timber LVL Formwork

The main components of timber LVL formwork include panels, beams, connectors, and accessories. Panels form the surface against which the concrete is poured. Beams, often called walers, are horizontal members that provide support and distribute the load evenly. Connectors, such as clamps and brackets, ensure the formwork remains intact. Accessories, including tie rods and form ties, are used to secure and align the formwork system.

Factors Influencing Timber LVL Formwork Prices

Material Quality and Price

The quality of the timber LVL used directly impacts the price. Higher-quality LVL with better load-bearing capacities and durability tends to be more expensive. Additionally, market conditions can affect the price of timber, which in turn influences the overall cost of LVL formwork.

Moreover, the source of the timber can also impact the price of LVL formwork. Timber sourced from sustainable forests or certified suppliers may come at a premium due to the eco-friendly practices involved in its production. This ethical consideration adds another layer to the pricing of timber LVL formwork, appealing to environmentally conscious buyers. Click here to learn more about eco-friendly,

Size and Complexity of the Project

The size and complexity of the construction project play a significant role in determining the formwork prices. Projects requiring more formwork materials or intricate designs may incur higher costs due to the increased material and labor requirements.

Furthermore, the location of the project can influence the pricing of timber LVL formwork. Projects in remote or difficult-to-access areas may face higher transportation costs for delivering the formwork materials, adding to the overall expenses. Factors such as terrain, distance from suppliers, and logistical challenges all contribute to the final pricing of timber LVL formwork.

Labor Costs and Timeframe

The cost of labor and the timeframe required for the construction project also contribute to the pricing of timber LVL formwork. Labor costs can vary depending on the location and availability of skilled workers. Additionally, projects with tighter schedules may require additional labor resources, potentially increasing the overall cost.

Moreover, the level of expertise and experience required for assembling the formwork can impact the labor costs. Complex designs or unique project requirements may necessitate specialized labor, which could come at a higher price. Balancing the need for skilled workers with budget considerations is crucial in determining the final cost of timber LVL formwork for a construction project. Learn more about skilled workers at https://www.brookings.edu/articles/creating-skilled-workers-and-higher-wage-jobs/

The Pricing Structure of Timber LVL Formwork

Understanding Unit Pricing

Unit pricing is a common method used to determine the cost of timber LVL formwork. It involves calculating the price per square meter or square foot of formwork material required for the project. This pricing approach allows for easy comparison among different suppliers and helps in estimating the overall cost accurately.

When considering unit pricing, it’s essential to factor in the quality of the timber LVL formwork being offered. Higher quality materials may come at a premium price but can result in better durability and performance, ultimately saving costs in the long run by reducing the need for frequent replacements or repairs. Some suppliers may also provide customization options for their formwork, allowing for tailored solutions that meet specific project requirements.

Bulk Order Discounts and Premiums

Suppliers often offer bulk order discounts for larger construction projects that require a significant quantity of timber LVL formwork. These discounts can help reduce the overall project costs. Conversely, for smaller orders, suppliers may charge a premium due to additional administrative and logistical overheads associated with handling smaller quantities.

It’s worth noting that the timing of the order placement can also impact pricing. Ordering well in advance can sometimes lead to better negotiation leverage with suppliers, potentially resulting in more favorable pricing terms. Additionally, establishing a long-term relationship with a supplier can lead to preferential pricing arrangements and better service levels, creating a mutually beneficial partnership in the construction industry.

How to Budget for Timber LVL Formwork

When it comes to budgeting for timber LVL formwork, there are several key factors to consider beyond just the basic material costs. Accurately estimating project costs is crucial for ensuring that your budget is comprehensive and realistic. This involves not only assessing the project requirements and determining the quantity of formwork materials needed but also accounting for any additional costs that may arise throughout the construction process.

One important aspect to consider is the quality of the timber LVL formwork materials being used. Higher quality materials may come at a higher price point but can offer increased durability and longevity, potentially saving money in the long run. It’s essential to strike a balance between cost and quality to ensure that the formwork meets the project’s requirements without exceeding the budget.

Estimating Project Costs

Accurately estimating project costs is crucial for budgeting timber LVL formwork. This involves assessing the project requirements, determining the quantity of formwork materials needed, and accounting for any additional costs such as transportation and storage. Obtaining quotes from multiple suppliers can aid in gauging a fair price range.

Another factor to consider when budgeting for timber LVL formwork is the labor costs associated with installation. Skilled labor is essential for ensuring that the formwork is properly constructed and meets safety standards. It’s important to factor in labor costs when creating a budget to avoid any surprises down the line.

Contingency Planning for Unexpected Costs

Construction projects often face unexpected challenges and cost fluctuations. It is advisable to allocate a contingency budget to mitigate any unforeseen expenses that may arise during the timber LVL formwork process. Having a buffer can provide peace of mind and ensure the project stays on track.

Additionally, considering the environmental impact of the timber LVL formwork materials is becoming increasingly important in construction projects. Opting for sustainably sourced materials may come at a slightly higher cost but can contribute to a more eco-friendly and socially responsible project. By factoring in these considerations when budgeting for timber LVL formwork, you can ensure that your project is not only cost-effective but also sustainable in the long term.

Tips for Negotiating Timber LVL Formwork Prices

Research and Price Comparison

Prior to finalizing any formwork purchase, conducting thorough research and comparing prices from different suppliers is crucial. This allows for better negotiation and ensures you are getting the best value for your investment. Look out for reputable suppliers with a track record of delivering quality products.

When researching suppliers, it’s important to go beyond just comparing prices. Take the time to read customer reviews and testimonials to get a sense of the supplier’s reputation for customer service and product reliability. Additionally, consider the supplier’s location and proximity to your project site. Choosing a supplier that is nearby can help reduce transportation costs and ensure timely delivery of your formwork.

Leveraging Bulk Purchases

If your project requires a substantial quantity of timber LVL formwork, consider leveraging bulk purchasing power to negotiate for better prices. Obtain quotes from multiple suppliers and use them as bargaining tools to secure favorable terms.

When approaching suppliers with bulk purchasing requests, it’s important to demonstrate your commitment and seriousness. Provide them with a detailed breakdown of your requirements, including the exact quantities needed and the timeline for delivery. This level of preparedness shows suppliers that you are a serious buyer and increases your chances of negotiating better prices.

Timing Your Purchases for Best Prices

The timing of your formwork purchases can also impact the prices you pay. Understanding market dynamics and seasonal trends in the construction industry can help you make strategic purchasing decisions. Buying during off-peak periods or when there are special promotions may result in cost savings.

For example, during the winter months, when construction activity tends to slow down, suppliers may offer discounts to stimulate sales. By planning your formwork purchases accordingly, you can take advantage of these seasonal fluctuations and secure better prices.

Furthermore, staying informed about industry events and trade shows can also be beneficial. These events often attract suppliers who are looking to showcase their products and offer exclusive deals. Attending such events can provide you with an opportunity to network with suppliers and negotiate favorable prices.In conclusion, understanding timber LVL formwork prices is essential for successful construction projects. By familiarizing yourself with the basics of timber LVL formwork, considering the influencing factors, understanding the pricing structure, budgeting effectively, and employing negotiation strategies, you can navigate the pricing landscape with confidence. Armed with this knowledge, you can make informed decisions and ensure you receive fair pricing for your timber LVL formwork needs.

Other resources: Where to Buy Quality LVL Timber for Formwork in Australia

Leave a Reply