Conduit fittings play an essential role in ensuring the safe and efficient operation of electrical wiring systems. These fittings are designed to connect and protect electrical conduits, which are the pipes or tubes used to house and protect electrical wires. Understanding conduit fittings and their importance in electrical wiring is vital for anyone involved in electrical installations or maintenance.

Understanding Conduit Fittings

When it comes to electrical installations, electrical conduit fittings play a crucial role in ensuring a safe and reliable system. These components are designed to connect and secure electrical conduits, providing a secure and efficient method for routing electrical wires. By protecting the wires from damage and maintaining compliance with safety standards, conduit fittings are an essential part of any electrical system.

Definition and Purpose of Conduit Fittings

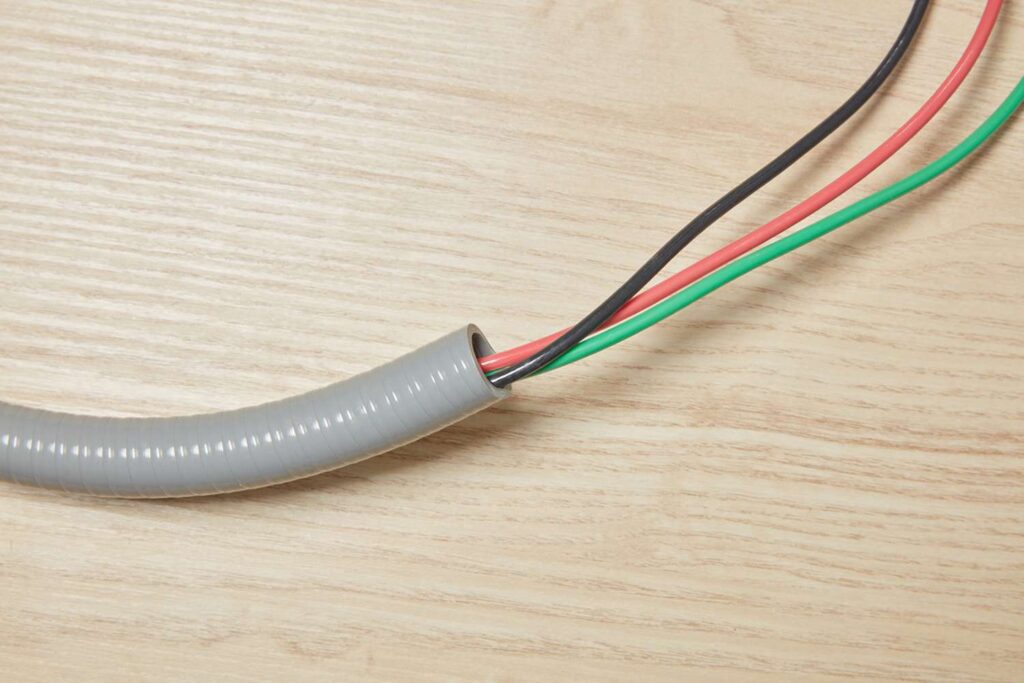

Conduit fittings, as the name suggests, are components used to connect and secure electrical conduits. Their primary purpose is to provide a secure and reliable method for routing electrical wires, protecting them from damage and ensuring compliance with safety standards. Conduit fittings not only establish a physical connection but also maintain the integrity of the electrical system.

Imagine a scenario where electrical wires are left exposed, vulnerable to physical damage or accidental contact. This could lead to short circuits, electrical shocks, or even fires. Conduit fittings act as a protective shield, enclosing the wires within a conduit and preventing any potential hazards. They also help in organizing and managing the wires, making maintenance and troubleshooting easier.

Different Types of Conduit Fittings

There are various types of conduit fittings available, each serving a specific purpose. Some commonly used fittings include:

- Conduit connectors: These fittings are used to connect two sections of conduit, ensuring a secure and watertight joint. They come in various sizes and materials to accommodate different conduit types and installation requirements.

- Conduit couplings: Couplings are used to join two conduit lengths together. They provide a strong and reliable connection, ensuring the continuity of the conduit system. Couplings are available in different styles, such as compression, set-screw, or push-fit, allowing flexibility in installation methods.

- Conduit elbows: Elbows are used to change the direction of conduit runs, allowing wires to navigate corners and obstacles. They come in different angles, such as 90 degrees or 45 degrees, providing flexibility in routing the conduits. Elbows can be made of various materials, including PVC, steel, or aluminum, depending on the application and environmental conditions.

- Conduit bushings: Bushings are used to protect wires from sharp edges where conduits enter electrical boxes or enclosures. They serve as a barrier, preventing the wires from getting damaged or frayed due to the rough edges. Bushings are available in different sizes and materials, such as plastic or rubber, to accommodate various conduit diameters and provide a secure fit.

The specific type of conduit fitting required depends on the application and the type of conduit being used. It is essential to select the appropriate fitting to ensure proper installation and system functionality. For example, in outdoor installations, weatherproof conduit fittings are used to protect the system from moisture and other environmental factors. In hazardous locations, explosion-proof fittings are employed to prevent the ignition of flammable gases or dust particles.

Furthermore, conduit fittings are not limited to just straight sections of conduit. They can also be used in combination with other fittings, such as tees, crosses, or reducers, to create complex conduit configurations. This allows for the customization of conduit systems to meet specific installation requirements.

Overall, conduit fittings are an integral part of electrical installations, providing the necessary connections, protection, and flexibility required for a safe and efficient electrical system. By understanding the different types and their purposes, electricians and installers can ensure the proper selection and installation of conduit fittings, resulting in a reliable and compliant electrical system.

The Importance of Conduit Fittings in Electrical Wiring

Electrical wiring is a crucial aspect of any building or structure, and ensuring its safety and efficiency is of utmost importance. One key element in achieving this is the use of conduit fittings. These fittings play a vital role in protecting electrical systems and optimizing their performance.

Safety Aspects of Using Conduit Fittings

When it comes to electrical installations, safety should always be the top priority. Conduit fittings contribute significantly to the overall safety of electrical systems. By providing a reliable grounding path, these fittings help prevent electrical shocks and minimize the risk of fires caused by wire damage or short circuits.

Electrical codes and regulations are in place to ensure the safety of both the occupants and the structure itself. The use of conduit fittings helps comply with these codes, providing an added layer of protection. This compliance not only safeguards against potential hazards but also instills confidence in the reliability of the electrical system.

Efficiency and Performance Enhancement

In addition to enhancing safety, conduit fittings also have a positive impact on the efficiency and performance of electrical wiring systems. By properly supporting and protecting electrical wires, these fittings reduce signal interference and electromagnetic interference (EMI).

Signal interference can occur due to various factors, such as nearby power lines or other electrical devices. Conduit fittings act as a shield, preventing external signals from affecting the quality of the electrical signals within the system. This leads to improved signal quality, reduced signal loss, and enhanced overall system performance.

Moreover, conduit fittings facilitate easier cable management and maintenance. With wires neatly organized and protected within the conduits, troubleshooting becomes faster and more efficient. In case of any issues, technicians can easily locate and address the problem, minimizing downtime and ensuring smooth operation of the electrical system.

Furthermore, the use of conduit fittings allows for future expansions and modifications with ease. As technology advances and electrical needs evolve, having a flexible wiring system becomes crucial. Conduit fittings provide the necessary flexibility, allowing for the addition or replacement of wires without major disruptions or costly renovations.

In conclusion, conduit fittings are essential components in electrical wiring systems. They not only ensure the safety of the system but also enhance its efficiency and performance. By complying with electrical codes, protecting against hazards, and reducing signal interference, conduit fittings play a vital role in creating reliable and robust electrical installations.

Selection Criteria for Conduit Fittings

When it comes to selecting conduit fittings, there are several important factors to consider. These factors can greatly impact the longevity and compatibility of the fittings with the electrical environment. One of the first considerations is the material used for the conduit fittings.

Material Considerations

Conduit fittings are commonly made from materials such as steel, aluminum, and PVC. Each material has its own set of benefits and considerations. For example, steel conduit fittings are known for their durability and strength, making them suitable for heavy-duty applications. On the other hand, aluminum conduit fittings are lightweight and corrosion-resistant, making them ideal for outdoor installations where exposure to moisture is a concern. PVC conduit fittings, on the other hand, offer excellent electrical insulation properties and are often used in residential applications.

When selecting the material for conduit fittings, it is important to evaluate factors such as durability, corrosion resistance, and electrical conductivity. These factors will help determine the most suitable material based on the specific application. For instance, in environments where corrosion is a major concern, such as coastal areas or industrial settings, stainless steel conduit fittings may be the best choice due to their exceptional corrosion resistance.

Size and Type Selection

Another crucial aspect of selecting conduit fittings is ensuring the proper size and type. The size and type of conduit fittings should match the size and type of the conduit being used. This ensures a secure fit and optimal performance, preventing issues such as wire damage and installation difficulties.

When determining the size of conduit fittings, factors such as the number of wires and wire gauge must be taken into account. It is important to choose fittings that can accommodate the required number of wires without overcrowding the conduit. Additionally, considering the bending radius required for proper installation is essential. Using fittings with a larger bending radius can help minimize stress on the wires and prevent damage during installation.

The type of conduit fittings also plays a significant role in the overall performance and functionality of the electrical system. There are various types of fittings available, including elbows, couplings, connectors, and adapters. Each type serves a specific purpose and is designed to facilitate different installation requirements. For example, elbows are used to change the direction of the conduit, while couplings are used to join two sections of conduit together.

By carefully considering the size and type of conduit fittings, you can ensure a secure and efficient electrical installation. Proper fitting selection not only prevents potential issues but also contributes to the overall safety and reliability of the electrical system.

Installation Process of Conduit Fittings

Installing conduit fittings is a crucial step in creating a safe and efficient electrical system. Whether you are working on a residential or commercial project, understanding the installation process is essential. In this guide, we will explore the pre-installation planning and step-by-step installation process for conduit fittings.

Pre-installation Planning

Before diving into the installation process, it is important to engage in careful pre-installation planning. This stage involves assessing the project requirements, determining the layout, calculating conduit lengths, and identifying the most suitable locations for fittings.

During the planning phase, it is crucial to consider the specific needs of the project. This includes understanding the electrical load requirements, the types of conduits and fittings needed, and any specific regulations or codes that must be followed. Adequate planning ensures an efficient installation process and minimizes the risk of errors or oversights.

Step-by-step Installation Guide

Once the pre-installation planning is complete, it’s time to move on to the step-by-step installation process. This guide will walk you through the necessary steps to install conduit fittings correctly.

Step 1: Measuring and Cutting Conduits

The first step in the installation process is measuring and cutting the conduits. Accurate measurements are crucial to ensure a proper fit for the fittings. It is important to use appropriate tools, such as a tape measure and a conduit cutter, to achieve precise cuts.

Step 2: Connecting Fittings

After cutting the conduits to the desired lengths, the next step is connecting the fittings. This involves selecting the appropriate fittings for the specific application and following the manufacturer’s instructions for proper assembly. It is important to ensure a secure and tight connection to prevent any future issues.

Step 3: Securing Fittings in Place

Once the fittings are connected, the next step is securing them in place. This can be done using various methods, such as using locknuts, screws, or clamps. It is important to follow the manufacturer’s recommendations and any applicable electrical codes to ensure a safe and reliable installation.

Step 4: Testing and Inspection

After completing the installation, it is crucial to test and inspect the conduit fittings. This involves checking for any loose connections, ensuring proper grounding, and verifying that the electrical system is functioning correctly. It is recommended to engage a qualified electrician to perform the testing and inspection to ensure compliance with safety standards.

By following these step-by-step instructions and taking the time to install conduit fittings correctly, you can create a reliable electrical system that will provide years of trouble-free service. Proper installation simplifies future maintenance or modifications and ensures the safety of both the electrical system and the occupants of the building.

Maintenance and Troubleshooting of Conduit Fittings

Regular Maintenance Tips

To keep electrical systems in optimal condition, regular maintenance of conduit fittings is necessary. This includes inspecting fittings for signs of wear or damage, ensuring tight connections, and cleaning any debris or contaminants. Routine maintenance helps identify and address potential issues before they cause significant problems or system failures.

Common Issues and Their Solutions

Despite proper maintenance, issues may arise with conduit fittings over time. Some common issues include loose connections, corrosion, and inadequate grounding. Prompt troubleshooting is essential to identify the root cause and implement appropriate solutions. This may involve tightening or replacing fittings, applying anti-corrosion coatings, or enhancing grounding measures.

In conclusion, conduit fittings play a crucial role in electrical wiring systems, providing connection, protection, and compliance with safety standards. Understanding the different types and selecting the appropriate fittings, along with proper installation, maintenance, and troubleshooting, ensures the safe and efficient operation of electrical systems. By prioritizing quality conduit fittings, professionals in the electrical industry can ensure robust and reliable electrical installations.

More to read: Choosing the Right Circuit Breaker for Your Electrical Panel

Leave a Reply